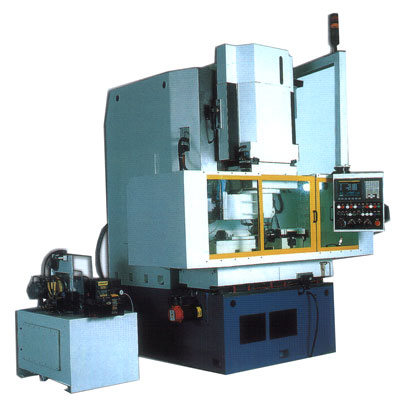

CNC Horizontal Gear Shaping Machine - STC4240J

| ◆He lubricant system is consisted of continuous lubricant system and intermittent lubricant system:The continuous lubricant system lubricates X axes feeding gear box,Y axes,Z axes worm gear box and cutter rest gear box.The intermittent lubricant system lubricates the ball beeline guide and ball guide screw of X axes,Y axes,Z axes. The X axes,Y axes ,Z axes of the tool and active frame(right)adopt SCHNEEBERGER high precishion(Accuracy class G3),high rigidity(Prelord class V3)ball beeline guide.X axes, Y axes,Z axes ball guide screws of the tool are high precision and high rigidity. |

| ◆The cutter rest principal axis of the tool can adopt changing rapidly structure (plate spring lockable,loosen with hydraulic pressure)or imported plastic nut lockable cutter. | |

|

FEATURES: |

|

◆ STC4040JCNC type of numerical control shaving machine is used in the finish mahining of straight gear,bevel gear and coupling gear.It is applied in the batch and large-scale production trades such as auto,tractor,engineering mechanism and motorcycle. The precision after razor can be to the grade of GB 10095-886.The roughness of the surface will be under Ra0.8. |

|

◆ The whole circulation of the razor is controlled by computer and showed by CRT.If the tool is failure,it can diagnose by itself and showed by the screen,which make the operator eliminate the failure quickly and well.In the distinct position of the tool can be equipped with the three-colors light. The light can clew the working position of the tool. The numerial control tool adopts FANUC(liquid crystal) system and has transmitted entrance (RS231C) with the notebook computer.During the circle machining of the tool,electromagnetism lock makes the safeguard door not open .In addition,any button may not stop the circulation (except for the urgent stop)to ensure the safety of the maschining.Only the person who specially assigns for the task can change the cutting specification.The control center of the tools is consisted of double gyration (control box gyration and cantilever gyration).The operation is convenient. |

|

◆The tool is five axes numerical control:X axes are separately controlled by a 6200 1kw type of FANUC servo electricity.FANUC servo electricity via a pair of high precision gears drives the plate righ-and-left movement(ordinate)and cutter rest board fore-and-aft movement through a pair of high rigidity ball guide screw after deceleration.Z axes is controlled by a 26/2000/1kw type of FANUC servo electricity.FANUC servo electricity via a pair of high precision worm gear (become thick)drives cutter rest board moving up and down(radia) through a pair of high precision and rigidity ball guide screw after deceleration.A axes is controlled by a M2/3000(0.5kw)type of FANUC servo electricity which drives the cutter rest corner by a pair of high precision worm gear and of high precision worm bevel gear.The cutter principal axis is drive by a 28/1500/7.5kw type of FANUC servo electricity through a pair of high precision gears after deceleration. The balance oil vat on the pillar supports the weight of the cutter rest board on the Z axes position. | |

|

SPECIFICATIONS: |

STC4240J |

| Workpiece |

The maximal diameter |

400mm |

| |

The maximal modulus |

8/6mm |

| |

The maximal number of teeth |

130mm |

| Cutter |

The maximal dianeter |

250mm |

| |

The maximal width of the cutter |

50mm |

| |

The fixed hole diameter |

63.5mm |

| Maximal space between finials |

500mm |

| Focus space between workpiece and shaving machine |

125~335mm |

| X axes axial feeding: |

The maximal journey |

150mm |

| |

Speediness |

500mm/min |

| |

10~150mm/min |

| |

The minimum increment |

0.001mm |

| Y axes tahgent feeding: |

The max journey ±20 |

40(±20)mm |

| |

Speediness |

125mm/min |

| |

10~80mm/min |

| |

The minimum inccrement |

0.001mm |

| Z axes radial: |

The maximal journey |

210mm |

| |

Speediness |

500mm.min |

| |

0.2~4mm/min |

| |

Minimum increment |

0.001mm |

| A axes corner range |

|

±20deg |

| |

The maximal Speed |

1.82rpm |

| |

The minimum increment |

0.001deg |

| The speed of the principai axis |

|

50~400rpm |

| |

Radial |

7.5kw |

| |

X axes servo electricity |

1.6kw |

| |

Y axes servo electricity |

1.6kw |

| |

Z axes servo electricity |

1.6kw |

| |

A axes servo electricity |

0.75kw |

| |