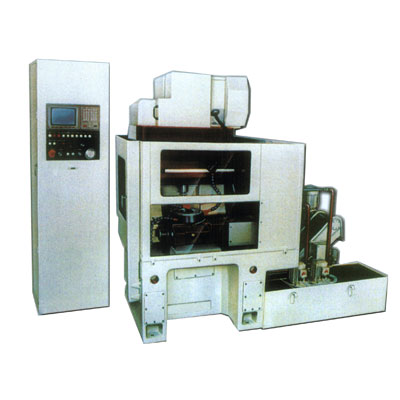

CNC Horizontal Gear Shaping Machine - SCC 2150 J

| ◆The primary motion of the machine is frequency controlled,and therefore is easy and simple to adjust.Hydrostatic guide way and hydrostatic bearings are adopted on the cutter head to ensure a high guiding accuracy and to enable the machine performing high speed cutting operations.The newly developed two-cam cutter relieving mechanism has substantially minimized the machine's vibration.The guideways are hardened and coated with a HNT wear-resistance coating.The hydraulic oil tank and coolant tank are independently separared. The cooling oil runs around the machine bed for an ideal thermal balance. High precision double-lead worm shafts are adopted on the cutter head and worktable. | |

|

FEATURES: |

|

◆ The model SCC5120CNC is a high-speed gear shaping machine with 4 axes controlled by a CNC system,and 3 of the 4 axes are under gang control.The machine can perform a strokerate up to 1750 strokes per minute and it has a wide range of circular feed and radial feed. Various cutting cycles can be performed on the machine through simple programming,and rapid circular federate is also available.The cutting speed can be automatically switched between rough cutting and finish cutting. |

|

◆The machine is featured in high rigidity,unique design,versatile functions and nice reliability,thus being well-suited for mass batch production of cylindrical internal and external gears, cluster gears with shoulders,segment gears and engaging gears. |

|

◆Equipped with an imported CNC system, the machine has a nice resetting accuracy and self diagnosis ability for troubles.Circular feed,radial feed and indrxing motion are all under digital and accurate control.Parametrization program compilation makes the machine easy and convenient for operation. |

|

◆Upon the user's special request,the machine can be provided with an automatic workpiece loading and unloading device,counter column for cutting shaft gears,helical guide for cutting helical gears as well as the deburring unit.

| |

|

SPECIFICATIONS: |

SCC 5120 J |

| Max.workpiece dia.extemal gear |

200mm |

| Max.workpiece dia.internal gear |

110+dmm |

| Max.module |

4mm |

| Max.face width |

40mm |

| Max.length of gear rack to be cut |

450mm |

| Max.helix angle |

40deg |

| Strokerate of cutters pindle per minute |

265~1050str/min |

| Circular feed of cutter/per min.(when cutter dia.is100mm),infinitelyvariable. |

20~550mm |

| Radial feed of worktable/per min.,infinitely variable |

2~4mm |

| Max.rapid travel of worktable per minute |

2000mm/min |

| Cutter spindle back-off at its upmost position |

>0.5mm |

| Column offset foroblique cutter releving |

±20mm |

| Max.stroke length of cutter spindle |

50mm |

| Diameter of worktable face |

320mm |

| Diameter of worktable hole |

100mm |

| Disance from cutter center to worktable center |

-50~185mm |

| Main drive motor power |

5.5kw |

| Main drive motor speed |

1500rpm |

| Circular feed servo motor power |

3.5kw |

| Circular feed servo motor speed |

1500rpm |

| Radial feed servo motor |

3.5kw |

| Radial feed servo speed |

1500rpm |

| Indexing servo motor |

3.5kw |

| Indexing servo speed |

1500rpm |

| Hydraulic pump motor |

1.5kw |

| Hydraulic pump speed |

1500rpm |

| Chip conveyor motor |

0.37kw |

| Chip conveyor speed |

1000rpm |

| Cooling pump motor |

0.25kw |

| Cooling pump speed |

2800rpm |

| Machine net weight |

5000kg |

| Machine`s overall dimensions(LxWxH) |

2010x1290x1982mm |

| |